TIMSONS

The book press company

Timsons Ltd, based in Kettering, Northamptonshire, is a family-owned business founded in 1896.

Timsons rotary book printers guarantee high profitability, innovation and a sturdy construction, and are customized to meet the clients specific production needs. Their ability to design and manufacture presses has been paramount for more than 100 years.

The construction of a Timsons press starts from the clients specific requirements of the products and markets they are targeting.

Latest technologies, from pre-press to book-binding, are installed on the machines to ensure the highest profitability. Attention towards the latest technologies and flexibility of build ensure the most proper technical solutions are met and the range of Timsons presses achieved success.

A customised rotary press

Every Timson is a unique project, different from the previous ones, and this requires continuous attention to research and development on every production aspect, from metal melting to final assembly. As each press has its own characteristics, all new machines are assembled and tested in production before they are delivered to the customer. Besides, the technical assistance service, supported by a network of agents and technicians we are proud members of, guarantees a prompt and precise intervention in any circumstance.

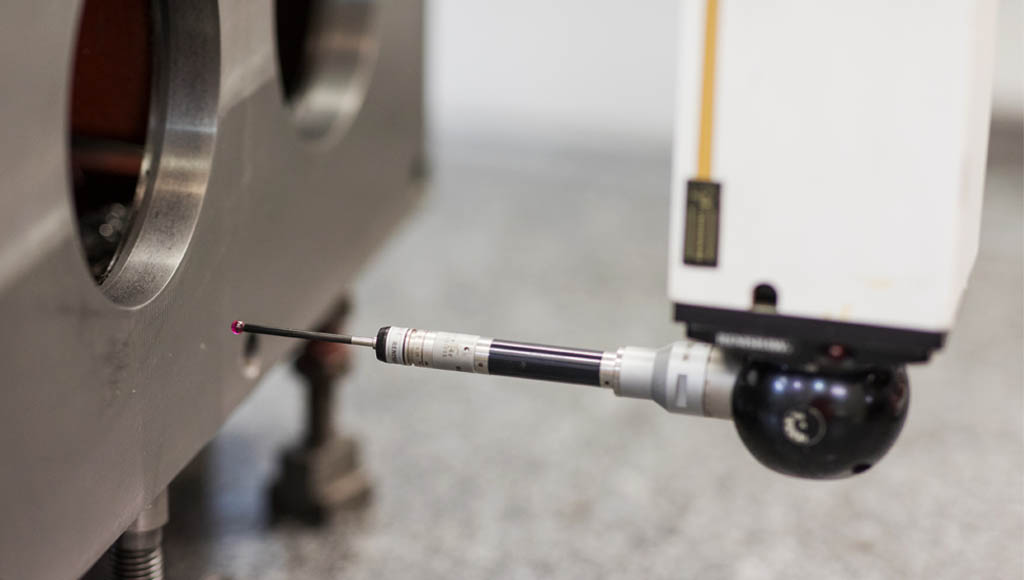

High quality construction

All Timsons products meet highest quality standards. Strong cast iron shoulders, mounted on a solid base, ensure a long productive life. Thanks to the mobile inking unit, operators on Timsons machinery have a safe and quick access to the print cylinders, allowing them to change the plates very quickly. The inker unit is equipped with three reciprocating rollers and three form rollers, the dampening can be brush or continuous or spray.

The printing cylinders are made entirely of special steel and are equipped with 50 mm wide bearers; the gears are in oil bath. This guarantees production reliability and reduced maintenance times. The circumference of the printing cylinders, the width and the configuration of the folder are customized to meet the client specific needs.

At the service of the printing world

Timsons’ numerous installations around the world have in fact replaced the traditional sheet feed press in the medium and short print runs for mono, two and four-colour books. The fast start-up with minimal waste and the exceptional flexibility in producing high foliation signatures, single or two up, allow our customers to offer a printing service “on demand”. The three-sided open signatures offer the highest quality and precision of folding with any type of paper starting from 18 grams per square meter. The vertical printing of the paper and the semi-automatic plate changer allow a single operator, assisted by a helper, to switch plates in less than 3 minutes, without breaking the web.

Folders

The M5 range of folders produces double parallel counter-fibre signatures in a wide range of formats, from 110 mm pocket sizes to 170 x 240 formats for textbooks.

The M6 range of folders offers all the features of the M5 folder and adds a long grain fold with the head closed.

The M7 range of folders produces a folded three-sided open fibre signature which can be set in the formats cut 2, cut 3, cut 4, cut 5 or cut 6. This can be improved by adding an option against fiber to offer a combination of formats based on the circumference of the press chosen. Most Timsons presses work with a folder from the M7 range, due to the increased foliation offered by the open three-sided signature.

Timsons today

Today, Timsons has become Timsons Engineering Limited. The company has flanked the production of printing machinery with the provision of services on behalf of third parties for the design and construction of any complex product. The company offers a full range of services ranging from a 1 kg castings foundry to 2.5 tons weight assisted by a CNC machining department for the subsequent finishing of castings. The foundry has two modern induction furnaces designed for the production of small and medium batches of all cast iron, grey cast iron and tempered spheroidal cast iron. The quality of the workmanship is guaranteed by the very long experience of the personnel and accredited with the ISOO 9001:2008 certification.